CNC Milling

Computer Numerical Control (CNC) Milling is the most common form of CNC. CNC mills can perform the functions of drilling and often turning. CNC Mills are classified according to the number of axes that they possess.

CNC Milling Machines We Use

YCM NSV102a machining centre

With 30 tool changer.

This has a spindle speed of 12,000 RPM, which is ideally suited to the machining of complex surfaces, i.e. 3D machining. This machine is also equipped with a fourth axis, which enables us to machine using a rotary table linked to the machine.

YCM MV66 machining centre

X=1020mm, Y=600mm, Z+=600

With 20 tool changer.

This machine has a spindle speed of 8,000 RPM, which is ideally suited to the machining of complex surfaces in tougher materials such as stainless steel.

Bridgeport VMC800 Machining Centre

X = 800mm, Y = 510mm, Z = 610mm.

This has a spindle speed of 12,000 RPM, which is ideally suited to the machining of complex surfaces, i.e. 3-D machining. This machine is also equipped with a fourth axis, which enables us to machine using a rotary table linked to the machine control.

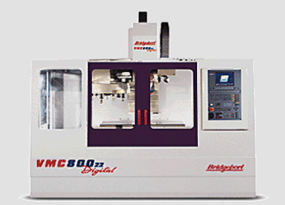

Bridgeport VMC600 Machining Centre x 2

This has a spindle speed of 8,000 RPM, and is also capable of 3D machining.

Although both Machining Centres are geared towards high-volume production, their modern control systems, and links to FeatureCAM, make them equally suitable for prototype and small batch work.

YCM NSV 66A

X=660mm, Y=510mm, Z=560

With 30 tool side mounted tool changer and through spindle coolant.

This has a spindle speed of 12,000 RPM, which is ideally suited to the machining of complex surfaces, i.e. 3D machining.

YCM NXV 560A

YCM NXV 560A x3

X=600mm, Y=410mm, Z=450

With 24 tool changer.

This machine has a spindle speed of 12,000 RPM, which is ideally suited to the machining of complex surfaces in tougher materials such as stainless steel