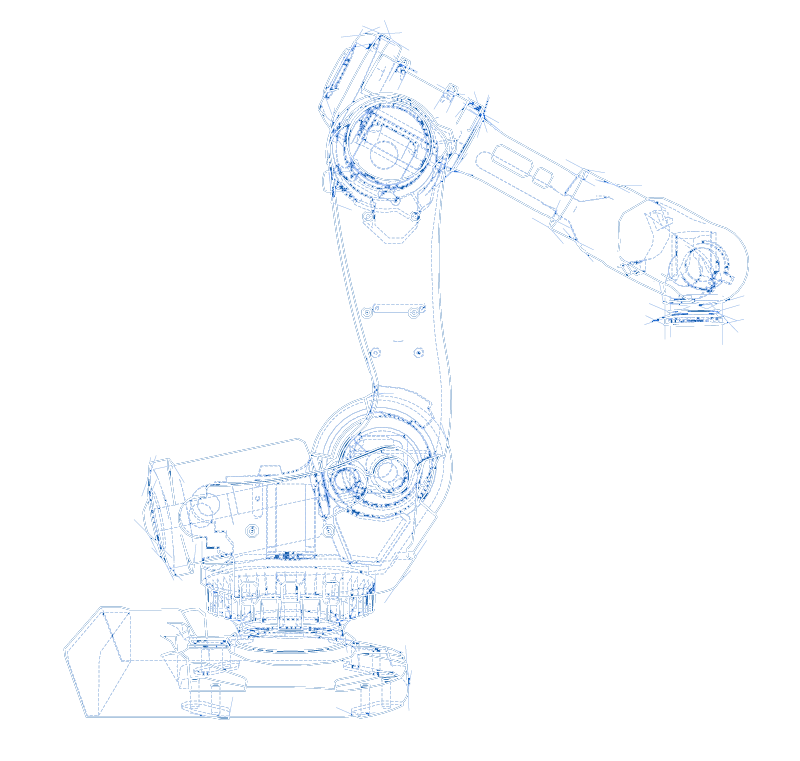

CNC Turning

Computer Numerical Control (CNC) Turning is the most common form of CNC. AC Precision Engineering has facilities for both CNC and Manual Turning.

Nomura – NN25 YB

CNC Sliding Head Lathe.

This production lathe will turn up to 26mm bar. Installed with a Iemca magazine bar feed this machine is suitable for high volume turned and milled parts.

Goodway GS2600-YS CNC Lathe

With a swing of 460mm, a maximum turning length of 750mm, a 254mm, 3-Jaw power chuck, a 62mm collet chuck, and a spindle speed of 4,000 RPM.

This machine is equiped with CF and Y-axis main spindle and a 12 station live tool turret with mill and drill Y axis. This machine is best suited to volume production of more complex parts.

Goodway GLS-200 CNC Lathe

With Bar feeding capacity of up to 50mm diameter.

With a maximum swing off 380mm over the bed and 500mm between centres.

Goodway GS260Y

This machine has a swing of 500mm over the bed

A turning length of 560mm an 8†chuck and a 65mm diameter bar capacity.

Doosan GT2100M

With a swing of 480mm, a maximum turning length of 785mm, an 8†chuck, and a spindle speed of 6,000 RPM.

Doosan PUMA 3100

Manual Turning

Colchester Master 2500 Manual Lathe, with a swing of 320mm, 1066mm between centres, and equipped with a Mitutoyo KM digital readout.

Colchester Truimph 2000 Manual Lathe, with a swing of 320mm, 1066mm between centres, and equipped with a Newall digital readout. A good robust prototyping lathe, suited to your larger and heavier components.

Hardinge Super Precision Manual Lathe, with a swing of 4.5 inch, 20 inches between centres and equipped with an Acu-rite 3 digital readout. This is an accurate, purpose-built collet lathe. This is also suited to precision prototyping.